Introduction: CNC Pen Lift

This instructable explains how to make a CNC pen-lift from an SG90 servo, two 4mm x 100mm nails, the spring from a ball-point pen, and a 3D printer.

The design accommodates pen diameters up to 14mm.

There is no pen-wobble when the pen is raised and lowered.

Construction is easy … all you need is access to a 3D printer, and basic workshop tools.

All STL and gcode files are supplied.

The estimated cost to build this pen-lift is less than $5.00 USD

Images

- Photo 1 shows the penlift attached to an experimental plotter

- Photo 2 shows a close-up of the assembled pen-lift

- The video shows the penlift in operation

Supplies

All parts are shown in photo1 above.

The SG90 servo, complete with horn and mounting screws, was obtained from https://www.aliexpress.com/

The following items were obtained locally

- 1 only M4 x 20mm bolt

- 1 only M4 nut

- 1 only ball-point pen spring

- 2 only 4mm x 100mm flathead nails

The yellow items were printed on a Voxelab Aquila 3D printer using 1.75mm diameter filament and a 0.2mm nozzle.

The 3D parts were designed using FreeCAD 0.2.

The STL files were created using Ultimaker Cura 4.13.1

Step 1: Features

This pen-lift was inspired by https://www.youtube.com/watch?v=hkwSPbMtB84&list=PL3BbZZ9thFk58og0_ueqBFIlwoCzLGlwf&index=64

Significant differences include:

- Only requires a single bolt

- Uses a captive nut

- The V-shaped hole

- prevents round pens from twisting

- accommodates hexagonal pens

- The use of construction nails for the guides

Step 2: The Servo Housing

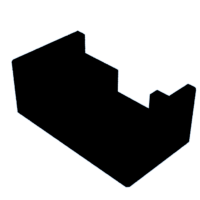

The servo housing holds the servo and the two nails that are used for guides

The pen-up servo horn position is shown photos 4, 5, and 6

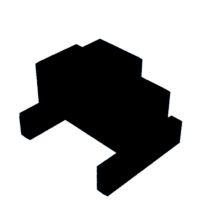

Step 3: The Pen Holder

The slot in the side of the pen-holder takes an M4 nut.

Position the nut mid-way down the slot then insert an M4 bolt through the top.

Don’t over-tighten the bolt … a finger-twist is sufficient to hold the pen.

Step 4: Assembly

Step 1

- Shorten the nails such that they will just protrude from the base of the servo housing (photo 1)

- Remove any ridges with a file

Step 2

- Rewind the ball-point spring around a nail

- It must be a loose fit

- Adjust its length such that it will push the pen-holder to the far end of the servo-holder.

Step 3

- Before inserting the nails into the servo-holder ensure that each side of the pen-holder slides freely under its own weight along a nail.

- This may require inserting a 4mm drill into the slider-holes to improve the fit.

- Don’t get carried away with the drill… any unwanted movement here will affect your plotter accuracy.

Step 4

- Insert one of the shortened nails through the servoholder, through the spring, through one side of the pen-holder, until it protrudes through the bottom of servo-holder (photo 3).

- The nail is a friction fit at each end of the servo-holder but the pen-holder should move smoothly.

Step 5

- Insert the other nail

- The nail is a friction-fit at both ends of the pen-holder but should pass freely through the holes in the pen-holder.

- Adjust the pen-holder hole sizes slightly if there is any tendency to stick.

- Don’t get carried away with the drill… any unwanted movement here will affect your plotter accuracy.

- Done

Step 5: STL Files

All STL and gcode files are attached

The STL and gcode files were created using Ultimaker Cura 4.13.1

Step 6: Summary

This instructable explains how to make a CNC pen-lift from an SG90 servo, two 4mm x 100mm nails, the spring from a ball-point pen, and a 3D printer.

The design accommodates pen diameters up to 14mm.

Construction is easy … all you need is access to a 3D printer and basic workshop tools.

All STL and g-code files are provided.

The estimated cost to build this pen-lift is less than $5.00 USD

Click here to view my other instructables.