Introduction: Operating Metal Abrasive Tools

The following outlines basic operation and etiquette when for shaping and buffing parts on the grinders and wheels.

Step 1: Using the Disc and Belt Sander

- Turn on the power and wait for the sander to come up to speed.

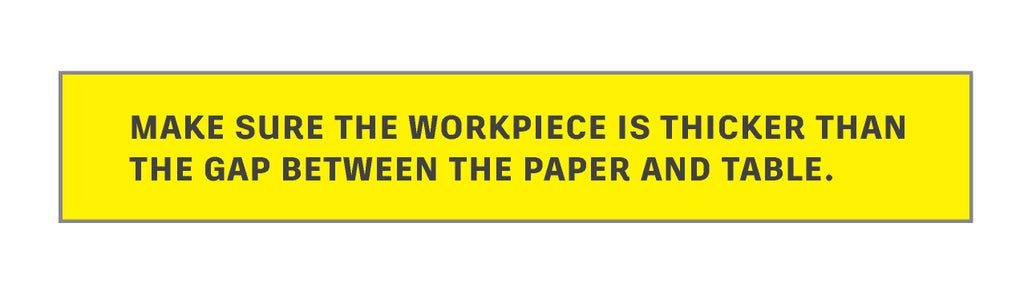

- Keep the material flat on the table.

- If you can’t do this, use a hand-held tool to shape your work.

- Slowly push the material into the sandpaper.

- Let the machine do the work for you; excessive force is not required.

- Do not sand on one spot; move the workpiece back and forth on the table.

- Stay in control of material - use two hands.

- Small parts require locking pliers.

- Turn off the power.

Step 2: Using the Deburring or Wire Wheel

- Turn on the power and wait for the machine to come up to speed.

- Only work in the 3:00 to 6:00 position.

- Slowly push the material into the wheel.

- Avoid exposing an edge to the wheel.

- Keep work slightly pointed down.

- Stay in control of material - use two hands.

- Small parts require locking pliers.

- Turn off the power.

Step 3: Using the Polishing Wheel

- Turn on the power and wait for the machine to come up to speed.

- Only work in the 3:00 to 6:00 position.

- Add compound to the wheel, using the block.

- Slowly push the material into the wheel.

- Avoid exposing an edge to the wheel.

- Keep material slightly pointed down.

- Stay in control of material - use two hands.

- Small parts require locking pliers.

- Turn off the power.

Step 4: Cleanup

- Brush off the table and clean up the area.

- Recycle scraps and put reusable pieces in the storage bin in the metal shop.

Step 5: Print Out This Guide

This course is available as a PDF that is attached to this step. Enjoy the grinders and buffers safely!