Introduction: Preparing the Printer

Creating the pack to send to the printer.

Step 1: Control Center

SEND THE JOB TO CONTROL CENTER

Click the printer icon to send the job to Control Center.

- This will save your le as a .CBM in the same directory as your .STL le.

- To print the le again, simply open the .CBM,

USING CONTROL CENTER

Control Center is the software used to pack a tray with parts and send to the printer.

- If there is an existing model on the grid, select it and click Remove.

- To add additional models, click Insert CMB.

- To add an additional copy of your model, select it and click copy.

- Click and drag your model to change their position if desired.

- Click Estimate Pack to estimate print time and material use.

- Jobs that use 100 cubic inches (or more) of support and model material require Shop Staff approval.

- Click Save As to save the job.

- Use this naming convention:

- team_ rstname_lastname_sheetname

- Use this naming convention:

- Click Build Job to send the job to the printer.

Step 2: Preparing the Printer

- Wear heat resistant gloves before opening the door or handling hot parts.

- When removing the build sheet it will be hot.

- Clear a space for it before opening the door.

- Open the door all the way.

PREPARING TO PRINT

Inside the oven is an aluminum plate called the build platform. A plastic build sheet needs to be placed on the build platform, and the model is built on the sheet.

A sheet can be reused, but the print must be made on an unused section.

Note: Different materials require unique build sheets. For example, printing with nylon requires the use of a nylon compatible build sheet.

Using the wrong build sheet may cause it to melt inside the printer.

- Open the lower printer door and empty the trash can.

- Insert the correct build sheet for your selected material.

- Ensure the build platform is clean.

- Any lament adhered to the sheet must be on the top side.

- Place the sheet on the platform and slide it to the back.

- Close the door and check the Vacuum Seal Indicator on the screen.

- If the sheet doesn't seal after a minute, reposition the seal.

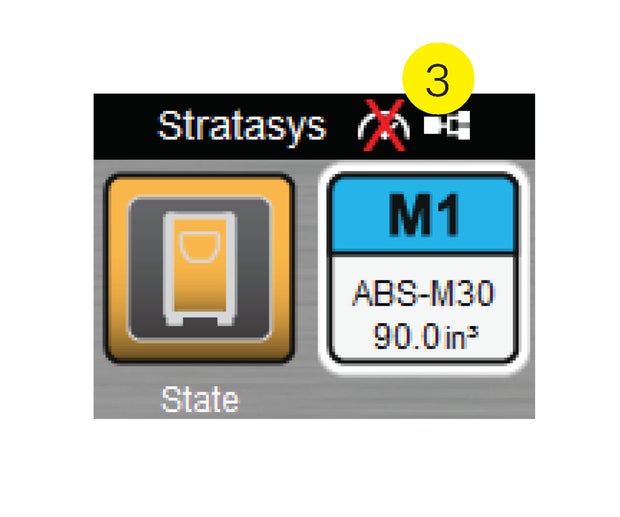

Understanding the Control Panel

- Machine State (touch for more info)

- Material and Support status

- S1 (support spool 1) is yellow, meaning that it is almost empty.

- Current job stats

- Use the arrows to scroll through current jobs.

- Completion data

- Percent completed

- Layers completed

- Elapsed time

- Expected completion time

- Material and support required and available

- Note that 125 cubic inches are required for this job. Remember that Shop Manager approval is required for all jobs of 100 ci or larger.

- Pause job

- Start job

- Cancel job

- Queue