Introduction: Split Gear for Broken Printer Paperfeed.

I love my old Photosmart printers for their features and keep them running since 15 years and liters of ink. I run them with CIS so they are really cheap, they print with 6 colors, have a LAN port so I can print via WiFi on my network and have tons of other usefull features.

Some years ago I had to replace the old capacitors, sometimes they show some ink system error that can be fixed via "secret" service menu.

This time the paper feed gear on one of my C5180 machines broke. It just made funny noises and didn't pull paper so I switched the CIS system to one of my backup C6280 machines. That's basically the newer model with a duplexer on the back. I seemed to be out of luck because the same gear broke again on that second printer just days later (or maybe my wife damaged it by trying to fix a paper jam and pulling the paper out in the wrong direction...never mind)

So I am installing a D7180 which is a shame because it got no LAN connection and my wife hates having to go to the printer to plug in her phone on the USB C cable.

I also got another C5180 and another C6280 but both printheads are not working on some colors...need to clean them...

It's just a small gear so it can't be that hard, right!

Supplies

You will need a 3D printer

Superglue + Activator

the STL file of the gear.

You need to widen the hole from 6 to at least 6.4mm!!!!

(just ask in the comments if you need another format. Original is Rhino)

I used a CAD program to reproduce the gear

a loupe app on my phone to do a macro shot

Cura for slicing

the FLsun QQS pro for printing with some basic PLA filament

Step 1: Replicating the Gear

After trying a 3D scanning app I realized it would be much easier to just take a macro photo of the gear parts and trace the gear on the computer.

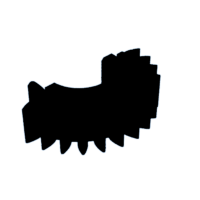

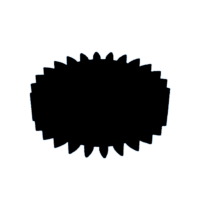

I traced one tooth and did a polar array to copy it 26 times around my hole.

The chamfer on the inner hole save you from elefant foot, that way the print will fit around a 6mm shaft without cleaning the inner hole.

If you print the inner ring raised and the teeth on a support, the teeth come out much cleaner that from the print bed. That's of course just me and my printer. The gear might come out perfectly with your settings or if you print in resin.

I then reglued my broken gear and took some measurements, printed the first version and compared it to the original.

I got it perfectly right by the 5th iteration and printed another one, a little beefed up, with some different settings.

Step 2: Taking Apart the Printer

...completely.

Yes. HP doesn't sell these parts for a reason. You would have to completely take apart your printer to get to that paper feed gear.

Here is a video of how much it has to be taken apart to get to the print head...it's more than double the steps to get to the paper feed shaft.

https://www.youtube.com/watch?v=YwQsFBvXJ_A

It can be done, has been done, and there are even people on the internet that will replace your gear for 18€ if you send them your printer or the shaft alone (the printer is 13kg!).

I don't want to take my printer apart.

Step 3:

Why not install the gear in place? I didn't find anything on Instructables or Google so it either had not been tried or published...I am gonna change that.

I now have an interlocking split gear that can be assembled right on the shaft.

As you can see on the picture where I had it installed, the hole was a little to small for the shaft. I took a 6mm drille an honed it out on the drillpress to make it fit and click right into place.

I still have not corrected that in my stl, so you will have to fix that or wait for me to fix it for you.

Step 4: Installing the Gear

Good light will help.

When you fix the gear to the shaft with super glue be careful with the infrared sensor above the gear. Tape it off with some painters tape to not damage it by fumes and activator.

I like to stand the printer on the side for gluing, apply a small drop and then a little activator.

The accuracy of your gear is not that important since the printer measures the paperfeed on an increment dial on the shaft so that it can even feed correctly with a wonky gear.

Step 5: Second Printer

The other printer had the gear just broken in one place so I could glue it together with tweezers right on the shaft.

3 out of 5 working again...2 printheads to clean.

Thanks for reading, I hope lots of printers can be saved from scap!

Participated in the

CNC and 3D Printing Contest