Introduction: Workholding and Offsets

It's important to determine workholding before CAM programming.

Workholding Options

The bed of the DMS is a thick acrylic sheet. It is drilled in a 6" hole pattern, with 3/8"-16 threaded brass inserts in each hole.

- Over-tightening a fastener can pull the insert out of the table.

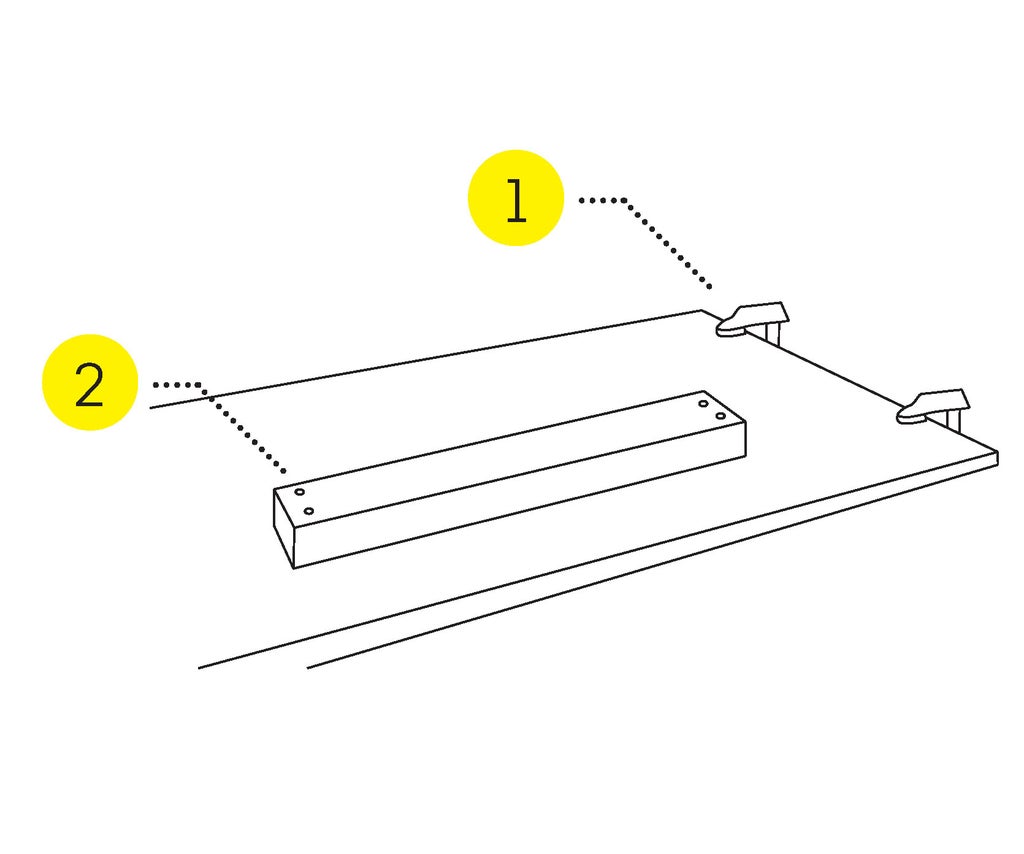

Spoiler Board & Clamps

- Clamp a spoiler board to the table.

- Screw your material to the spoiler board. Use a minimum of 4 screws, and more for large projects.

Make sure that the tool will not collide with a clamp or screw.

- Brass screws will not damage the tooling in the case of a collision.

Threaded Inserts & Step Clamps

- Hold the work with a step clamp.

- The clamp should be level.

- Support the end of the clamp with a step block.

- Insert a threaded stud through the clamp into the table insert.

- Tighten a nut on top of the clamp.

- Use a minimum of 4 clamps, and more for large projects.

Make sure that the tool will not collide with a clamp.

Double Sided Tape

- Clean the table and material.

- Tape will not stick to damp or dusty materials or MDF.

- Apply tape to your workpiece.

- Press firmly to adhere the material to the table.

- Test the adhesion before starting to cut your project.

Tape works better on short wide items than tall narrow ones.

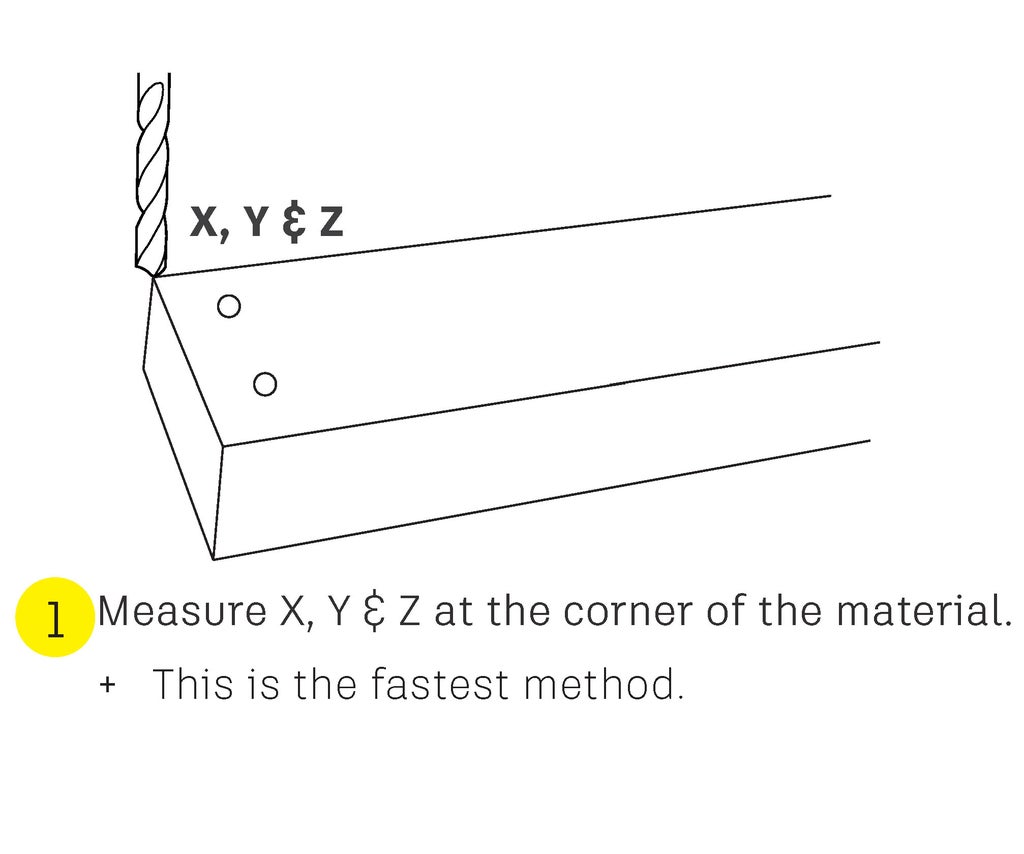

Step 1: Establish Your Work Offset

Set the Work Offset (G54)

You must use the same Work Coordinate System (WCS) you chose in your CAM program.

You have 3 options when setting the Work Offset.

- X, Y & Z at the corner

- X & Y at the corner, Z in the middle

- Air pass

- X & Y at the corner, very high Z

Move the tool tip to Work Home

- Perform a tool change.

- Choose a drill bit or small diameter tool to make finding your WCS easier and more accurate.

- Jog the tool to Work Home.

- Press MDI. (F4)

- Type G53 & press Cycle Start.

Set X & Y at the corner

- Press ESC to go up one level.

- Press User. (F5)

- Press Load Zero Offsets. (F2)

- Press Load G54 Offsets. (F1)

- Press Clear All Offsets. (F6)

- Press Yes. (F1)

- Press Exit. (F7)

- Press Load G54. (F1)

- Press X & Y. (F1) & (F2)

- The status for each axis will change to loaded.

- Press Exit three times. (F7)

- This will return you to jog mode.

You have set your Work Coordinates for X & Y. Now, you must decide where to set your Z axis.

Step 2: Set the Z Work Coordinate

Reposition and set Z

The following steps will set Z, and also enable the machine to calculate exactly where the tool tip is located, even when moving the B & C axis.

- If needed, jog the machine to where you want to set Z.

- Press MDI. (F4)

- Type G48S0 (zero, not the letter) & press Cycle Start.

- Type G53 & press Cycle Start.

- Type D[tool number] & press Cycle Start.

- Type G48S1 & press Cycle Start.

- Press ESC.

- You should be at the jog menu.

- Press User. (F5)

- Press Load Zero Offsets. (F2)

- Press Load G54. (F1)

- Press Z. (F3)

- This will set your Z offset.

Confirm that your WCS has been correctly set.

- Press Exit (F7) 3 times.

- Press MDI. (F4)

- Take a photo of the screen.

- Include the X, Y & Z values.

- This will allow you to return to Work Home in the case of a problem.

- Type G54 & press Cycle Start.

- Check values of X, Y & Z.

- Z should be 0.

- X & Y will be 0, unless you jogged the machine to set Z.