Introduction: Workholding

The ShopBot table at Pier 9 was custom made by Shop Staff to make workholding faster and easier. Treat it nicely.

- Never cut into the table more than 1/32".

- Carefully measure your material thickness to avoid deep cuts in the table.

- See Shop Staff before using screws as a workholding method.

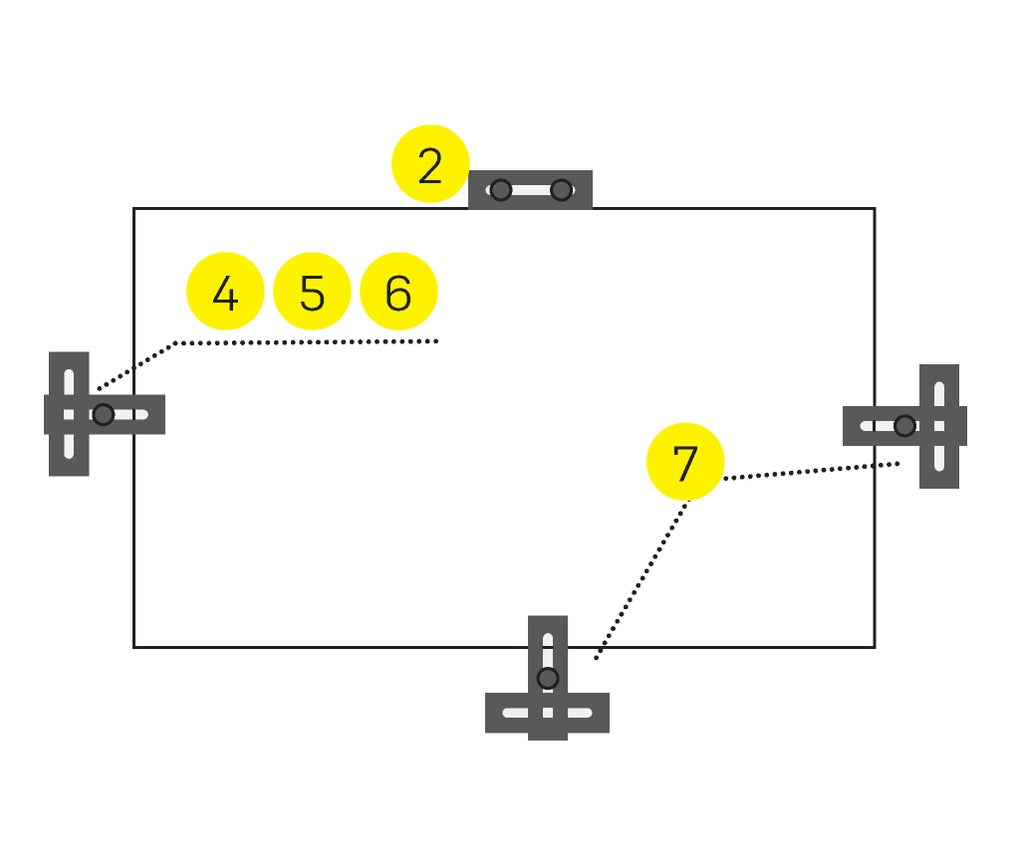

Full Sheet (4' x 8') Workholding

When cutting full sheets, use clamps to hold the corners and edges to the table.

- Square the workpiece to the ShopBot table.

- Use the red and black clamps to hold each corner and side of the material.

- Only use plastic and rubber clamps - no metal.

- Use a minimum of 6 clamps; one on each corner and one on each long edge.

- Use more clamps when possible.

Partial Sheet Workholding

The table has a grid of over 400 holes. Each hole has a threaded metal insert that nylon bolts can be screwed into. The nylon bolts secure the hold down blocks that hold your workpiece.

- Blow out the insert with compressed air.

- Place a hold down the block at on the table, at the back of the workpiece.

- Place the long edge of the block against the workpiece.

- Screw in two bolts, using washers.

- Hand tighten the bolts.

- Use a wrench to tighten an additional 1/4 turn.

- Do not overtighten.

- Place a block a few inches from your workpiece.

- Place a second block on the first, with one end on top of your workpiece.

- Attach them with a nylon bolt.

- Add a minimum of two more hold downs.